Rock Mechanics and Earth Science Lab

The lab have a variety of apparatus for conducting experiments, such as rock cutting and drilling tools and other geotechnical testing equipment. These tools and instruments are used to perform experiments on rock and soil samples, simulating different geological conditions and studying their mechanical properties, physical characteristics, and behavior under stress and strain.

The lab also have advanced analytical instruments for conducting chemical and mineralogical analyses of rock samples, such as X-ray diffraction (XRD).These instruments allow for the identification and characterization of different minerals, textures, and structures in rocks, providing insights into their composition and formation processes.

Additionally, Rock Mechanics and Earth Science Lab have geophysical instruments and software for studying the geophysical properties of rocks and subsurface structures.

Dericks Praise Shukla

Dericks Praise Shukla

Core drilling machine

- Core drilling employs a hollow punch to remove a clean core of material to determine the quality, density, strength of a material and various other properties.

- At one end of the drill is core bit, that is impregnated with diamonds or tungsten carbide to make it easier to cut the rock.

- Core bit is attached to a reaming shell which reams the hole to the desired diameter size and also helps to stabilize the core bit.

Core cutting machine

- Used to cut cores of varied sizes of concrete, stones, other building materials and metallic specimens.

- Depth of the cut is adjusted by pressing blade carriage. It can be locked in position with the help of a lever.

- Water is continuously recirculated for blade cooling and flush cuttings.

- Machine has sturdy base with pillar support in which rack & pinion is provided for adjustment in height and penetration assembly.

Core polishing machine

- To reach the flatness and parallelism tolerances, a polishing phase is usually required.

- Machine is convenient for grinding and polishing sample of granite, marble and other natural stone.

- A sample holder is provided in which the sample is moved towards the diamond impregnated polishing blade.

- The cooling water system is used to cool the specimen and grinding wheel.

Brazilian test apparatus

- To determine Indirect Tensile Strength.

- Mostly rocks in biaxial stress fields fail in tension when one principal stress is compressive.

- Size of core drilled specimen is between 50 mm-100 mm and only cylindrical specimen is used.

- A rigid frame, two Circular jaws,, a hydraulically load applied, pressure gauge.

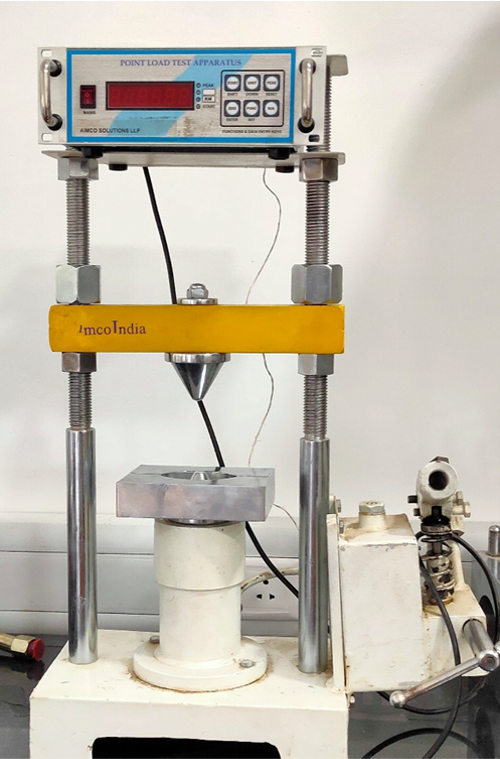

Point load test apparatus

- To determine indirect uniaxial compressive strength (UCS).

- Performed in field as well as in laboratory.

- To determine indirect uniaxial compressive strength (UCS).

- Performed in field as well as in laboratory.

- Any type of core drilled specimen can be used as like cylindrical (generally), rectangular or any irregular shapes.

- A rigid frame, two point load platens, a hydraulically activated ram, pressure gauge and a distance measuring device.